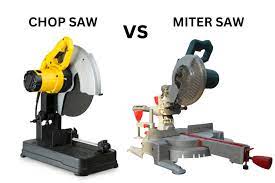

Choosing the right saw for your woodworking projects can be confusing.

We’ve all been there, haven’t we? You’re ready to buy a new power tool, but you don’t know which one is best for your needs. And then you end up buying two tools because neither of them is exactly what you wanted in the first place. It’s frustrating and expensive.

Check out this blog post that compares miter saws vs chop saws so that next time you go shopping for a power tool, it will be easier to make an informed decision.

Difference Between Chops Saws vs Miter Saws

The difference between a chop saw and a miter saw is that a chop saw cuts 90-degree angles and is larger while a miter saw is smaller, cuts beveled angles. Chop saws are larger than miter saws and get used for their sheer brute force while a miter saw operates in a similar way to a chop saw, so you would think the two are interchangeable when it comes to tasks. A chop saw motor typically generates over 5 horsepower, whereas a miter saw manages 2.5 horsepower.

What Is a Miter Saw?

A miter saw is a powerful, portable, compact tool. The name comes from its ability to make crosscuts (cuts across the grain of the wood) and beveled cuts (cut at an angle). It’s better for cabinetwork or any project that requires accuracy. You can use it to cut molding around windows and doors as well as baseboard, crown molding, panel molding, picture frame pieces, and shelves.

What Is a Miter Saw Used For?

The most common reason people decide to purchase a miter saw is for basic cutting tasks like cutting 2 x 4 boards down to size or making decorative moldings for cabinets. But because it features accessories such as guide poles and various blades, there are many other jobs a miter saw can perform.

Miter Saw Pros

- Portable, compact

- Cuts across the grain

- Cuts angles

- Accurate

- Many accessories that expand miter saw’s capabilities

Miter Saw Cons

- Avoids large, thick or heavy woods

- Slower speed

- Less power than a chop saw

Summary of Miter Saw Pros and Cons

A miter saw is one of the most versatile tools you can have. It can cut across the grain, make angled cuts and it is fairly accurate. Keep in mind that its capabilities are limited to cutting smaller pieces because of its size and motor power. The great thing about using a miter saw for any project is the many accessories available such as guide poles and various blades. These accessories allow you to do tasks such as ripping boards (cutting them lengthwise), kerfing (cutting thin strips from wide boards), dadoing (placing grooves on your workpiece), and making moldings. Additionally, the parts of a miter saw are easily replaceable and customizable to suit your needs.

What is a Chop Saw?

A chop saw is a type of circular saw that features a lower blade guard and a wider base. The top handle can be easily rotated to provide extra stability when cutting large pieces of wood. It has a lower blade guard because it’s designed for quickly making large cuts in thick or heavy pieces. It doesn’t have the same versatility as a miter saw, but its sheer power makes it ideal for larger projects such as flooring installation, notching joists, and framework.

What Is a Chop Saw Used For?

Chop Saws are used mainly for framing walls and floors (rough carpentry) and any sort of precise crosscutting is not recommended. If you need to make precise cuts, with either an accurate miter saw or table saw.

The most common reason people decide to purchase a chop saw is for framing walls and floors. But because it features accessories such as guide poles and various blades, there are many other jobs a chop saw can perform.

Chop Saw Pros

- High powered.

- Heavy-duty frame/stability bar.

- Great at making large cuts in thick pieces of wood, but also good for accurate crosscutting if you set the blade depth correctly.

Chop Saw Cons

- Not portable – this is not a hand-held tool. It’s very heavy and cumbersome to move around, so keep that in mind before purchasing one.

- This type of saw must be mounted to a workbench or used with sawhorses if you plan on working outside.

- Slower speed.

Summary of Miter Saw Pros and Cons

A chop saw is a great tool for notching joists and frameworks, but it has limitations when it comes to making precise cuts (angles). It’s high powered but its heavy-duty frame/stability bar also makes it difficult to move around. Keep in mind that this is not a hand-held tool. You must mount it on a workbench or use sawhorses if you plan on working outside.

If you’re planning on using your chop saw frequently, make sure you purchase one with an anti-vibration feature; this will help minimize the strain placed on your arms while cutting. Chop saws are great at quickly making large cuts in thick pieces of wood, but you can also make accurate crosscuts if you set the blade depth correctly.

Can a Chop Saw Cut Angles?

If you own a chop saw, it should be able to make angled cuts. However, because of its design and lack of an adjustable miter feature, this is not ideal for projects that require precise angles. If you need accurate angles, use a miter or table saw instead.

Cutting Materials

Which saw is better for cutting certain materials? Let’s find out.

Wood

- Miter Saw: A miter saw is perfect if you want to cut small pieces of wood. You can fasten a clamp or workbench to the bottom of your saw to secure your material as you’re working on it.

- Chop Saw: If you’re planning on making larger cuts in thick pieces of wood, then a chop saw would be the better choice.

Metal

- Miter Saw: If you ever need to cut metal, a miter saw is definitely the better choice. Aluminum and steel are softer metals that can easily be cut using a miter saw without dulling your blade in the process.

- Chop Saw: Cutting through harder metals such as iron or steel requires a high-powered chop saw with a blade designed for cutting harder metals.

Concrete

- Miter Saw: As long as you don’t cut right on the concrete, a miter saw should be able to make nice clean cuts. Just set the depth accordingly and use a circular saw blade designed for cutting through different types of materials.

- Chop Saw: If you need to cut all the way through a piece of concrete, then a chop saw is your best option.

Masonry

- Miter Saw: A miter saw can make large cuts through masonry but it will take a long time and you risk causing excessive vibration to the blade while cutting.

- Chop Saw: A chop saw is your best option when it comes to cutting through masonry. Its high-powered, heavy-duty frame/stability bar makes it possible for this tool to cut through brick, stone, and other hard masonry materials.

Composites

- Miter Saw: A miter saw is perfect when cutting through composites. As long as you set your blade depth correctly, you can easily cut composites such as plywood and fiberglass without dulling the blade or creating a lot of vibration.

- Chop Saw: If you’re cutting through hard composites such as metal/wood composites, then a chop saw is best. It can handle these hard materials without any issues.

Plastic

- Miter Saw: Easily powerful enough to cut through plastic.

- Chop Saw: Can handle plastics, but a miter saw is the better choice.

Bottom Line: Chop or Miter Saw?

A chop saw is best when cutting through thick pieces of wood, masonry materials, or metal. A miter saw will cut through all the same materials but it isn’t designed for tough jobs so it’s not recommended to use one if you have access to a chop saw.

Mulch is essential for keeping your garden healthy and beautiful, but it can be expensive.

You want to have a lush garden without breaking the bank. There are many mulching alternatives available that work just as well as real mulch but cost much less.

We will show you how to choose the best mulch alternatives for your garden so that you don’t spend more than you need to.

1. Pea Gravel

Pea gravel is a popular alternative to mulch that looks great and can come in many colors. It’s not just for lakes, but also on walkways paths patios driveways playgrounds as it works amazingly well at adding natural variation with its color variations

Mulching Pea Gravel creates an aesthetic appeal unmatched by any other method used due to the round size smooth shape some people might have seen while walking along with one of these bodies if water or another place where they are commonly found naturally However others may know this material from landscaping projects often done around homes such us when someone wants a cheap way create a beautiful flowerbed without having spend hours digging holes.

Pros

- Good for weed suppression

- Good for retaining moisture and aeration

- Looks great and can be color-coordinated to fit any décor

Cons

- Can be expensive

- Doesn’t last as long as other types of mulch because it can become compacted down.

- Doesn’t hold up well during the winter against snow and ice.

Cost

The price of pea gravel ranges from about 25 dollars to 60 cents per cubic yard. Sometimes online retailers offer small 5-pound bags at around $10-30 each for use in smaller areas or just as an aesthetically pleasing look.

2. Pumice rock

Pumice is a naturally occurring volcanic rock that can be ground up to be made into pumice stone, which is commonly used in the bath and shower industry.

This material works very well for mulching because it retains moisture while letting air get through. It’s porous so water can drain easily through it while at the same time keeping the soil hydrated, just like real mulch would do.

The pores in this natural material allow plant roots to breathe instead of suffocating them by drowning them with too much water, while also helping to prevent washouts during heavy rains or when water runs off of other surfaces such as roofs or driveways by soaking it up before it goes anywhere else.

Pros

- Retains moisture while still allowing air in, which makes it perfect for plants that need to dry out between watering.

- Is porous, letting water drain through easily while at the same time keeping soil hydrated like real mulch would do.

- Helps prevent washouts during heavy rains or when water runs off of other surfaces such as roofs or driveways by soaking up water before it goes anywhere else.

Cons

- Can be expensive if you want it in a color other than natural grey.

- Doesn’t hold up well during the winter against snow and ice because of its light color.

Cost

The cost of pumice ranges from about 30 to 40 dollars per cubic yard depending on the size, shape, and brand. Sometimes online retailers offer small 5-pound bags at around $10 each for use in small areas or just as an aesthetically pleasing look.

3. Rubber Mulch

This is one type of mulch that doesn’t get a lot of love from some people because they think it looks tacky or cheap, but there are a lot more benefits to using rubber mulch than meets the eye though. Livestock farmers use it for bedding and other types of livestock containment to keep their animals safe and healthy, so if you love the idea of your garden looking like a farm then this may be the perfect mulch alternative for you.

Pros

- Is very durable and doesn’t break down easily.

- Helps suppress weeds greatly because it’s dark in color and acts as a heat sink that absorbs sunlight during the day and then radiates that heat out at night to help warm up soil that would otherwise remain cold.

- Retains moisture really well since it’s made from recycled rubber tires which absorb oils and dirt particles over time.

- Can last for years without showing signs of breaking down even after repeated exposure to sun ice rain snow or hail.

Cons

- Doesn’t look very good aesthetically because it’s black.

- Can get very warm during the day, which can burn plants if they are too close to it.

- Is one of the more expensive mulch alternatives out there.

Cost

The cost of rubber mulch is around $25-45 per cubic yard depending on where you purchase it and what brand it is. Sometimes online retailers offer small 5-pound bags at around $10 each for use in small areas or just as an aesthetically pleasing look.

4. Newspaper and/or Cardboard

This may sound like an odd thing to put in your garden but there are plenty of reasons why this could be a really good idea so don’t knock it until you try it. For instance, newspaper is one of the best materials for weed control because paper does not let light through at all so it deprives emerging weeds of their light source. This is also a great way to recycle old newspapers or cardboard that would otherwise just be thrown away into something that actually has use instead of being out in the landfill where no one will ever see it again.

Pros

- Is very inexpensive and can be used several times on different plants before being thrown away.

- Is really good for weed control since it doesn’t allow any light to pass through which means weeds won’t grow through it either.

- Won’t become waterlogged like organic mulches do heavy rains because there are no pores in it to hold water.

- Can help keep soil moist when used under organic mulches too because they will absorb any excess moisture before it has a chance to make the newspaper wet.

- Is made from recycled materials which also helps save natural resources that would otherwise need to be mined or harvested in order for something new to be made instead of being reused again.

Cons

- Is not very aesthetically pleasing since it can look messy, especially if you’re using paper instead of rolled-up cardboard.

- Doesn’t retain moisture very long after heavy rains so waiting until the top layer of soil is dry again before adding organic mulch on top is important.

Cost

Newspaper usually costs around $10-20 year depending on how many newspapers you have to buy, so it will typically last for at least a year or two before you need to add more. Rolled-up cardboard is around $2-3 per square foot.

5. Leaves

These are one of the most common types of organic mulches out there and should be considered by anyone who has a garden bed that has been cleared from weeds but not replanted yet because they’re a good way to get your garden beds ready for new seeds or seedlings very quickly and inexpensively, plus they look really nice when spread across soil in a thick layer too. Plus, if you mix in some other organic materials then you’ll have a garden that is good for the environment and your wallet too.

Pros

- Is free if you have some trees on your property or live next to a neighbor who doesn’t mind you taking their leaves for this purpose.

- Is dark in color which will help it absorb heat from the sun during the day and only lose that heat at night instead of continuing to radiate it out all night long like lighter colored mulches do.

- Won’t let any light through at all, meaning weeds won’t be able to grow through them either.

- Great for weed suppression even underneath organic mulch because they’re so thick that no new weeds can emerge through them anyways.

- If mixed with other organic materials, then soil will become richer in nutrients over time because these other organic materials are added.

Cons

- Doesn’t stay moist for very long after rain or watering depending on how thick it is, so waiting until the top layer of soil dries again before adding more mulch is important to prevent rotting plant roots underneath where they can’t get any air.

- You’ll need to rake up leaves that fall into garden beds during autumn every week or two which could be more work than some people want to deal with just for mulching their garden beds even though it’s free if you have trees nearby.

- Fire hazard. These will catch fire very quickly if they’re dry, plus once burned they release carbon dioxide back into the air too fast and don’t behind any ash like wood does, so this should never be used as mulch around shrubs or any other plant that could easily catch fire.

Cost

Is free if you can find a neighbor willing to let you take their leaves for this purpose.

6. Grass Clippings

Another common type of organic mulch that people use for their garden beds is grass clippings because these are free if you have a lawnmower and grass always seems to be growing too high in some areas anyways.

Pros

Free as long as you have a lawnmower or someone nearby who does.

Is green so will provide the benefits of natural ground cover just like regular grass does, which means it can help keep soil moist, suppress weeds from emerging too quickly, and will also warm up soil a bit more than other mulches might during wintertime.

It’s good at preventing weed growth since grass has strong roots that grow very close to the surface of soil where they absorb nutrients from soil directly rather than having to send their roots down into soil like other plants do.

Can be mixed with leaves or other organic mulches very easily since grass clippings are small enough in size to mix in well with most other material types without needing much extra work.

Cons

It’s free but only lasts for around 6 weeks before drying out and warming up too much, which means it’ll need to be replaced 4 times per year on average if you want to use this type of mulch everyday throughout the entire growing season. This is probably too often for many people so they opt instead to spread it once at the beginning of each season then wait until just before wintertime when rain will be more plentiful again before adding fresh mulch for insulating purposes.

It’s not dark in color so won’t absorb heat from the sun during the day and continue to radiate that warmth out all evening long. At night, it’ll lose any heat that was absorbed throughout the day which can be a problem if you have very cold winter weather since this will cause colder soil underneath mulch once again.

Cost

None, if you have a lawnmower and grass.

7. Pine Needles

Pine needles are another type of organic mulch material which can be used around plants to help protect them from extreme weather conditions too, although they’re mainly used because they have an aesthetically pleasing appearance for flower beds or other types of formal garden arrangements where appearance matters more than anything else.

Pros

- Is green so will provide the benefits of natural ground cover just like regular grass does, which means it can help keep soil moist, suppress weeds from emerging too quickly, and will also warm up soil a bit more than other mulches might during wintertime.

- It’s good at preventing weed growth since pine needles have strong roots that grow very close to the surface of soil where they absorb nutrients from soil directly rather than having to send their roots down into soil like other plants do.

- Can be mixed with leaves or other organic mulches very easily since pine needle clumps are small enough in size to mix in well with most other material types without needing much extra work.

Cons

Is not free because you have to buy this type of mulch from a store unless you happen to have a pine tree on your property or know someone who does.

Won’t last very long since it’s not dark in color so won’t absorb heat from the sun during the day and continue to radiate that warmth out all evening long. At night, it’ll lose any heat that was absorbed throughout the day which can be a problem if you have very cold winter weather since this will cause colder soil underneath mulch once again.

Cost

About $10 per 32-gallon bag of mulch.

8. Hay or Straw

Another common type of organic mulch material is hay or straw because these are free if you own some farmland or happen to know someone nearby who does who would be willing to share with you for no charge.

Pros

- Is free if you know someone nearby who’s willing to share some with you for no charge.

- Won’t last very long because it loses its nutrients quickly and becomes dry which means it won’t insulate heat as well either which can make the soil underneath colder once again during wintertime.

Cons

- Is not dark in color so won’t absorb heat from the sun during the day and continue to radiate that warmth out all evening long. At night, it’ll lose any heat that was absorbed throughout the day which can be a problem if you have very cold winter weather since this will cause colder soil underneath mulch once again.

- It’s also good at preventing weed growth like pine needles are.

Cost

None, if you know someone nearby who’s willing to share some with you for no charge or if you own farmland and can use it yourself.

9. Cocoa Bean Hulls

Cocoa bean hulls make another type of organic mulch material which can be used around plants to help protect them from extreme weather conditions too since they’re dark in color which means they’ll absorb heat during the day and release that warmth into surrounding air all evening long which makes soil underneath more hospitable for growing things like roots and bulbs once again.

Pros

- Is green so will provide the benefits of natural ground cover just like regular grass does, which means it can help keep soil moist, suppress weeds from emerging too quickly, and will also warm up soil a bit more than other mulches might during wintertime.

- Is good at preventing weed growth since cocoa bean hulls have strong roots that grow very close to the surface of soil where they absorb nutrients from soil directly rather than having to send their roots down into soil like most plants do.

- Can be mixed with leaves or other organic mulches very easily since cocoa bean clumps are small enough in size to mix in well with most other material types without needing much extra work.

Cons

- Is not free because you have to buy this type of mulch from a store unless you happen to sell bags of cocoa beans for a living which would make it free if you could then use the leftover cocoa beans.

- Is not dark in color so won’t absorb heat from the sun during the day and continue to radiate that warmth out all evening long. At night, it’ll lose any heat that was absorbed throughout the day which can be a problem if you have very cold winter weather since this will cause colder soil underneath mulch once again.

Cost

About $10 per 32-gallon bag of mulch.

10. Compost

Compost is a type of organic mulch material that’s made from rotting plant waste which can be very beneficial to have around plants if you want those plants to grow well because the decaying matter will provide those plants with lots of nutrients as it breaks down.

Pros

- Is green so will provide the benefits of natural ground cover just like regular grass does, which means it can help keep soil moist, suppress weeds from emerging too quickly, and will also warm up soil a bit more than other mulches might during wintertime.

- Is good at preventing weed growth since compost has strong roots that grow very close to the surface of soil where they absorb nutrients from soil directly rather than having to send their roots down into soil like most plants do.

- Can be mixed with leaves or other organic mulches very easily since compost clumps are small enough in size to mix in well with most other material types without needing much extra work.

- Is good at helping soil retain moisture so it won’t dry out too quickly during hot summer months which is helpful for preventing plant roots from drying out and dying if they don’t get watered very often. Compost also has nutrients inside of it which can help plants grow so they’ll be healthier than before you added this type of mulch onto the surface of soil where they’re growing.

Cons

- Is not free because you have to buy this type of mulch from a store unless you happen to sell bags of compost for a living which would make it free if you could then use the leftover compost.

- Is not very dark in color so won’t absorb heat from the sun during the day and continue to radiate that warmth out all evening long. At night, it’ll lose any heat that was absorbed throughout the day which can be a problem if you have very cold winter weather since this will cause colder soil underneath mulch once again.

- Can smell like rotting plant waste which might not be appealing for some people who don’t like strong smells around their homes or yards.

Cost

About $10 per 32-gallon bag of mulch.

11. Landscape Fabric

Another common type of organic mulch material is landscape fabric because it’s usually free if you ask for some at local garden centers or landscape supply stores who may be willing to give away some old pieces they have just lying around their store cutting room floor which are usually going to be too small in size to sell anyway.

Pros

- Is usually free if you ask a garden center or landscape supply store for some old pieces they may have lying around, specifically ones that are just right for your needs and not too large or small which is unlikely to happen since most stores use the same type of mulch material over and over again because it’s such a common type of material.

- Won’t last very long because it loses its nutrients quickly and becomes dry which means it won’t insulate heat as well either which can make the soil underneath colder once again during wintertime.

Cons

- Not dark in color so won’t absorb heat from the sun during the day and continue to radiate that warmth out all evening long. At night, it’ll lose any heat that was absorbed throughout the day which can be a problem if you have very cold winter weather since this will cause colder soil underneath mulch once again.

- Can also become nutrient-deficient over time which means weed growth underneath organic mulches like landscape fabric is common since weeds will grow quickly without having to send roots deep down into soil to find nutrients first.

- Is usually not free unless you know someone who’s willing to give away some for no charge or they’re planning on using them themselves but then don’t need anymore which are unlikely possibilities most of the time.

Cost

None, if you know someone nearby who’s willing to share some with you for no charge.

Do you know the difference between a gable window and a dormer window?

Gable windows are often confused with dormer windows, but they actually have very different purposes.

Dormers were originally created to add extra living space to an attic or roof area by adding another room on top of the house.

Gables are usually part of the main structure, which makes them stronger than dormers, so they can be used for larger openings like doorways and larger windows.

Both types of windows bring in light, but there are also some significant differences you should be aware of before deciding whether one is right for your home improvement project.

If you’re thinking about installing either type of window in your home then it’s important that you understand what each one looks like and how it works so that you can make an informed decision about which ones would look best in your home and provide maximum functionality based on your needs.

What Is A Gable Window?

A gable window is a form of a casement window, which means it has a large swinging door that opens outward from the side.

Gable windows usually have four panels in them and open from one side to allow for maximum ventilation during warm weather when you need it most.

When the frame is closed, they form a triangle shape on top of your house that makes a decorative addition to your home exterior.

Depending on where you live, gable window frames can be made out of vinyl or aluminum with one or more glass panels instead of solid wood boards.

For people who don’t want to sacrifice style for functionality, gable windows are an excellent choice because they make a statement about your home without making you lose too much square footage.

What Is A Dormer Window?

A dormer, on the other hand, is not a form of a casement window.

Instead of opening outward like gable windows do, dormers open inward toward the center of your roof.

Dormers are designed to add extra space in your attic if you don’t have enough room for a full second floor or another room upstairs. They can also provide you with additional storage space that doesn’t take away from your living area below. If you add insulation and drywall along with any other materials needed to complete this type of project, then you could even use it as an extra bedroom. In fact, dormer windows are sometimes called “bump-out windows” since they create a bump-out effect in your roof when you add an extra room or space.

While gable windows are aesthetically pleasing, dormers don’t add to your home’s exterior appearance. In fact, it may actually detract from the overall aesthetic design of your house because people who pass by will notice that something is different about your roofline and not in a good way.

What’s The Difference Between A Gable Window And A Dormer Window?

Although it would be easy to assume that since both windows are near the top of the home, they must serve similar purposes.

That’s not actually correct though because there are many key differences between a gable window and a dormer window.

Both types of windows bring in light, but there are also some significant differences you should be aware of before deciding whether one is right for your home improvement project.

Dormers were originally created to add extra living space to an attic or roof area by adding another room on top of the house

They’re placed high in a roofline, which makes them better for smaller spaces that need extra headroom rather than more open areas with plenty of vertical space

Dormers have a vaulted ceiling, which means they’re good for bedrooms or living areas that need more headroom.

Gable windows are often part of the main structure instead of being a separate addition, which makes them a better choice for larger openings like doorways and larger windows.

They can usually accommodate bigger pieces of furniture inside because there’s plenty of vertical space to move around.

Gabled roofs are very common in residential construction since they provide plenty of headroom for an attic or loft area as opposed to dormer windows which only give you extra height without taking up any room on the inside of your home.

Since their roofs slope inward toward the top, they don’t provide quite as much headroom as you would get from an actual gable window.

Types Of Dormer Windows

Although there are many different kinds of dormers, the two most common ones are located at either end or along a sidewall.

Most homes have dormers that help with extra space in the attic, but they can also provide additional exterior features like a flower box or even a window bench where you can sit and enjoy the view outside your home.

Hip Roof Dormer

A hip roof dormer is flat at the bottom and slopes upward to meet the other roof sections at an angle instead of forming a right-angle corner.

Bonnet Dormer

This type of dormer has curved sides and looks like it’s wearing a bonnet or straw hat.

Nantucket Dormer

This is another hip roof-style dormer with curved sides and lines that give it a pointed look at the top.

Lucarne Dormer

This type of dormer has straight sides and an angled bottom edge, which makes them appear like diamonds from one aerial view.

Flat Dormer

As the name implies, this kind of dormer is flat and may not be as dramatic as other dormers when seen from street level or below.

Shed Dormer

A shed roof dormer looks like two separate roofs that join together to form one small triangular-shaped addition on top of your home.

Pedimented Dormer

A pedimented dormer has a triangular shape to it, but the bottom edge curves slightly upward instead of being completely straight.

Flared Gable Dormer

This type of dormer has an angled roofline with an arched top edge that resembles Mt. Fuji when viewed from above. It’s one of the most dramatic-looking dormers and is perfect for homes with exterior features like turrets or towers that need a focal point.

Wall Dormer

A wall dormer is flat and very similar in size to your home’s exterior wall since it does not extend beyond it except for its sloping roof along the top edge.

Pyramidal Dormer

This style looks a bit like a pyramid with its square bottom edge that slopes up to meet the top at an angle.

Recessed Dormer

A recessed dormer has a square shape and is set back into your home’s exterior wall instead of being inset out from it or flush with it on both sides.

Link Dormer

A link dormer looks like two gable roof dormers stacked on top of each other, but they are connected together by their flat surfaces along the bottom edge instead of having pointed roofs.

Eyebrow Dormer

This style is also referred to as a flying eyebrow because it kind of looks like one when you see the side view of your home’s roofline.’s similar in size to a gabled dormer, but it doesn’t have any sides that stick out or protrude from the home.

Benefits of Dormers and Gable Windows

– They can usually accommodate bigger pieces of furniture inside because there’s plenty of vertical space to move around.

– As opposed to being a separate addition, which makes them a better choice for larger openings like doorways and larger windows.

– They allow for more insulation than do dormer windows because the roofline prevents air from getting trapped between two separate sections.

– If you have multiple seasons in your area, gabled roofs provide better coverage in winter to help keep out the snow and ice while letting in plenty of sunlight during the summer months.

– They give your home a traditional cottage, country or rustic look with their slanted rooflines and exposed beams.

– They can add plenty of extra space to your attic for storage if you have enough room, which makes it an excellent choice for rooms that need some extra organizational help.

Wrapping Up

Dormer windows are often more dramatic-looking than gable windows because they have slanted roofs that protrude from the home. For this reason, dormers offer a better choice for larger openings like doorways and larger windows. They also allow for more insulation since the roofline prevents air from getting trapped between two separate sections of your home’s exterior wall or framing structure.

Gabled roofs provide better coverage in winter to help keep out the snow and ice while letting in plenty of sunlight during summer months due to their sloped design on top which helps direct light into areas where it is needed most.

Dormers can give your home a traditional cottage, country or rustic look with their slanted rooflines and exposed beams as well as adding extra space to your attic for storage if you have enough room.

When you’re shopping for a new bed, it’s hard to know what to look for and how much you should spend. There are so many different parts that all serve different functions.

We created this blog post to explain the different parts of a bed and their functions in an easy-to-understand way. This is great information if you’re looking into buying a new mattress or just want to learn more about your current one.

Read on below for our handy guide on the parts of a bed and how they work together.

The Headboard

The headboard is the large backboard of your bed that you lean against. They come in all different sizes, shapes, and colors. Some are upholstered (featuring fabric) while some may be solid wood or metal.

The bed frame rests directly on top of the headboard. The best way to measure for a new headboard is from the floor to the desired height. That gives you an accurate reading when determining how much space you have to work with.

The headboard is made up of a number of sections, including:

- Headboard slat: This holds the headboard together and can support larger mattresses.

- Headboard brackets: These are small pieces of metal that connect the headboard slat to the bed frame, creating a secure hold.

- Headboard posts: This acts as a connector between your headboard and your bed frame. The posts may include decorative finials at the top and connecting knobs for easy assembly.

The Side Rails

Also known as sideboards, these sturdy pieces make up a portion of each side of your bed frame. You can also call them “bed frames” if you prefer not to use this term because it can make some confusion when describing a bed to someone else.

The side rails help to support the bed structure and ensure that your new mattress has a sturdy home. The side rails are attached directly to the headboard and footboard of the bed, which makes them an important part of durability for not only your mattress but also your new box spring.

Bed Side Rail vs. Bottom Side Rail

A bottom side rail sits on the ground and attaches to your bed frame. This is surrounded by slats that create a more comfortable sleeping surface for you.

A bedside rail goes up right next to your mattress, which can help keep kids from falling out of bed or making it easier to get into bed. Having a rail here also helps with durability around where you sleep because this is an area that typically has some wear and tear.

The Footboard

The footboard is another large backboard of your bed that acts as the bottom of your bed frame. It’s usually smaller than the headboard so you can lean against it with ease. This piece of furniture may include some storage space, either on its own or built right in to the footboard of your platform bed.

There are two major types of beds: hard-sided (headboards & footboard) and soft-sided (platform beds).

- Footboard Slat: This is the section on top of your footboard, which can add to its overall sturdiness.

- Footboard Brackets: These make up a small piece of metal that connects the footboard slat to your bed frame and offers increased support and durability.

The Legs

No matter what style of bed you have, four legs are always involved. They should go straight down the corners of your bed frame to give it additional support. The best height for these is about half an inch above the floor because that’s where they’ll rest when you put on your mattress. For adjustable bases, make sure you measure properly so that your gap isn’t too large.

Box Spring

A box spring sits right underneath your mattress. It provides great back support while also raising your mattress for extra storage space underneath. If you sleep with a partner, this is a good option because it allows both of you to use the same surface without feeling like one person is sleeping higher than the other.

Cut Slats

The cut slats are thin pieces of wood that rest between your mattress and box spring. The amount you need depends on how much room is in between them, but it’s usually around eight to ten. They’re spaced about an inch apart, making sure that there isn’t too large of a gap or not enough (if they’re too close together). These help to keep your bedding in place while also providing extra support for your body when relaxing.

Cleats

The cleats are what connect the headboard, footboard, and side rails together. You can either screw these in or attach them with brackets, creating a sturdy foundation without any gaps in between. This is why measuring is so important: you don’t want any room for your bedding to slip away and get wrinkled behind the headboard or footboard.

Box Spring

A box spring is a sturdy foundation that rests underneath your mattress. It’s built with springs inside it to provide great back support, but also helps to lift your mattress up for more storage space. Usually, box springs come in pieces so you’ll need one part for each side of the bed frame. Make sure you measure both sides before purchasing anything.

Different Bed Designs and Parts

Daybed

A daybed is a great option if you’re looking for a less bulky bed frame. It has a much different design from any other bed, with no headboard or footboard included. This is because it’s made to look like a bench that can be used as extra seating during the day and gets converted into an extra sleeping space at night. If you have kids, this can help keep them off your main mattress so they don’t mess up the sheets or get drop crumbs onto the sheet below.

Futon

A futon is another type of daybed that can convert into a bed at night. Most futon mattresses are firm to give you support no matter which side you’re sleeping on, but they also come in soft options if you want something more comfortable during the day that still offers good back support when lounging.

Platform Bed

This style of bed doesn’t have any box spring or springs underneath the mattress; instead, its design is meant to provide you with support on top of the frame. Many platform beds are already made sturdy without extra tools like legs or cleats, but if yours weren’t, you can always add them later for increased support.

Waterbed

A waterbed is becoming less popular thanks to the popularity of foam mattresses, but they’re still a great option for those who don’t like sleeping on such soft surfaces. The mattress is most commonly made with water inside it, which provides increased pressure relief and deep compression support. It works best if you don’t have any back problems, but this style does make up for its lack of comfort with sturdiness and durability.

Airbed

An airbed is similar to a waterbed in that there’s a large amount of air inside the mattress, but it doesn’t require any water. It provides great back support and pressure relief, making it a healthy option for those who need more comfort when they sleep. This type of bed is also great if you have allergies or asthma since it won’t allow dust mites and other allergens to get trapped inside like with regular mattresses.

Murphy Bed

A Murphy bed is a great way to save space during the day since you can hide your bed underneath cabinet doors. This type of bed doesn’t have any legs or support though, so it’s not meant for guests who will be sleeping on it. If intended for yourself, you’ll need to make sure there’s enough room in between the floor and cabinet bottom for your mattress, but also make sure you have storage space if your mattress is too tall.

Canopy Bed

A canopy bed is a bed with a canopy above it made from sheer fabric or curtains. This type of bed is best if you want something that will keep you protected from any draft, but isn’t meant to give much support at all. It’s important to have another foundation underneath your mattress since the canopy only gives shade and looks pretty, not good sleeping conditions.

Topper

A topper is an excellent option that adds some extra cushioning to your sleep experience. Most are made with memory foam inside them, which helps with pressure relief through conforming exactly to your body’s curves rather than pushing against them. However, some are just flat sheets without any foam at all, so you can choose which option is best for you.

Wood paneling is a popular design choice for homes and businesses, but it can be difficult to keep looking new.

A lot of people don’t know that you can distress wood paneling yourself with just a few common household items. It’s easy and cheap, so if your panels are looking worn or dated this is the perfect solution.

Here’s how to distress wood paneling in five steps:

1) Sand the surface.

2) Clean the surface and remove all dust.

3) Apply a stain.

4) Paint with white or gray paint, diluted with water.

5) Sand again.

1. Prepare The Surface

We’ll start by sanding the surface. This will roughen up any paint you apply, which is perfect because our goal in this step isn’t just a little bit of coverage; we want to be able to cover as much area with high-quality paints that stick like glue.

Carpets are also something worth protecting so use tarps or drop cloths where needed and carefully peel off the old tape from previous projects before beginning yours today too.

Adding marks or flaws to the surface is an excellent way of taking on that aged look. You could leave dents and scratches from hitting a hammer, pry bar, pound nails against it in order to create dimples for stability—some even whip pieces chains carefully along with them. There’s nothing wrong if you decide not to add any decorations at all too; however, adding some character can help solidify your illusion as well so do what feels right for yourself.

2. Clean The Surface and Remove All Dust

It’s important to make sure the surface is clean before adding any paint, varnish or other finishes.

Dust can cause imperfections on your surface, so it’s crucial that you take the time to remove all dust from the piece. Use a clean cloth to wipe away any dust particles left on the surface of the wood paneling.

3. Apply Stain To The Wood Paneling

Now that your surfaces are clean and dry, you’re ready to apply stain—or paint if desired. If you’d like to create an old-timey look, use a dark brown stain rather than painting with white or gray paint diluted with water. This will give your walls an authentic distressing worn effect however whether this is what you are looking to do or not is still up to you. We are going for the aged look that will help our paint job last longer, which means it won’t take much time at all.

For this kind of painted wood paneling effect, use a brush and paint thinner (or water) mixture in order to make your gray paint go onto the surface smoothly without any issues or dried-up finishes clogging up the works. If you’d like, you can skip the sanding step all together too. There are many ways to achieve this style so have fun with it.

4. Sand The Wood Paneling Once Finished Painting Over It

Once your paint has completely dried over the surface of the wood paneling, take sandpaper and scour it so that it becomes rough again.

This will help your next layer of paint stick to the surface more easily—and not flake off.

5. Repeat If Needed

If you applied too little paint or watered down your mixture too much, you’ll only need to do this one more time for good measure. However, if needed, applying a second coat is no problem thanks to your preparation work beforehand.

Can You Paint Wood Paneling?

Just like with drywall, wood paneling can absolutely be painted. However, it must be clean and free of dust care of the “Sand The Wood Paneling” step.

If you’re painting over paint that is peeling, worn, or faded it is also important to remove any loose paint before adding your new layer(s) on top by either sanding or using a chemical stripper. If tearing away chunks of old paint makes you nervous, use chemical strippers instead.

What Is The Best Color To Paint Wood Paneling?

When it comes to making a choice on what color or shade to paint your wood paneling, it is important that you choose a color that is in tune with the surrounding areas.

Use colors that are in harmony with one another and don’t be afraid to try out new shades when doing so. You can even go for the “distressed” look if this appeals more too.

There’s no need for a primer since wood paneling was dipped in a protective substance in order to make it weatherproof back in the day. Make sure you choose a quality paint brand for best results when painting wood paneling inside your home today though, as an aged painted effect will only happen if the material is primed first.

Do not skimp on the paint either as you’ll need quite a bit of it too in order to cover up all of your wood paneling.

What Paint Will Stick To Veneer?

If you are working with antique tung oil finishes, it’s best to avoid brushing on wood stains as this may cause some bubbling in the finish due to the different kinds of finishes used—which leaves us at about three steps max. An alternative method (if one prefers not to distress) would be good old fashion distressing too; focus on adding dents here and there for that old-world look.

You can also brush on some matte polyurethane over the distressed wall for added protection though striping off wallpaper first is always a good idea regardless of your choice in finish.

Can Wood Paneling Be Lightened?

Yes, however, just like stripping wood paneling and refinishing it to give it a fresh look, lightening the color can be done—but not in one step.

Wood panels that have been painted over many times without much sanding in between will take multiple applications of stain (or paint) where getting rid of any initial layer(s) still left on the surface is key. This means applying your chosen solution (stain or paint), allowing it to dry, then sanding lightly amongst each step until satisfied with the results.

Broker mirrors are easy to break, but hard to replace.

If you’re like most people, your bathroom is probably one of the busiest rooms in your home. You use it every day and there’s always someone else using it too. It can be hard to keep everything looking clean and new when you have so many people touching things all the time. This means that even small issues with your mirror or sink start to become big problems very quickly.

We’ve written this blog post for everyone who has ever broken a broker mirror (or any other glass surface).

By following our tips on how to fix a broker mirror yourself, you’ll save money by not having to call in an expensive professional repairman.

Here are 7 basic steps to repairing a cracked mirror:

1) Clean the mirror thoroughly

2) Apply stabilizer film

3) Apply epoxy resin to cracks

4) Let the epoxy set

5) Peel the stabilizer film away

6) Remove any excess epoxy resin

7) Clean the mirror again

Step #1: Clean the mirror thoroughly

A broken mirror can be very unsightly. You want the surface of the mirror to be as clean as possible so that the repair epoxy does not stick to the dirt when it is applied.

The resin typically comes in a plastic syringe applicator. Carefully nudge the edge of the epoxy syringe beneath the film and press the back of the syringe to inject epoxy between the surface of the mirror and the stabilizer film. The epoxy will harden on top of the cracks, so it’s best to lay the mirror on a flat surface and not disturb it during this time. It’s best to hold the razor or utility knife at an angle to help get as close to the epoxy as possible.

Step #2: Apply stabilizer film

After the epoxy has been set, peel away the top layer of paper and then place a new piece of stabilizer film over the cracks making sure that all surfaces are covered. The stabilizing film will keep water from penetrating into the mirror. It also prevents the resin from moving on to other parts of your mirror. This means that t his step is very important. Some kits are used with an applicator squeegee for this process, but it’s usually easier to use your hands. You can even wear rubber gloves if you want to make sure your hands stay clean throughout the process.

Step #3: Apply epoxy resin to cracks

Once the stabilizer film has been applied, apply the resin over the cracks by pressing it into the grooves with your finger or the plastic applicator tip. The mirror will become cloudy as the fisheye effect builds within the surface of the mirror; this is normal. Don’t try to wipe away any excess, just let it dry and then cover any areas that feel rough after 15 minutes have passed. If you find that you have a rough spot on a previous application, use a razor blade or a utility knife to cut another piece of stabilizer film and lay it over the top of the first glue-down of resin before applying more. Let this layer dry for 15 minutes and use your finger or the squeegee to smooth it out.

Step #4: Let the epoxy set

The adhesive will become cloudy over time but keep its original shape. It’s best to let it sit overnight before you remove any excess resin that may have built upon the surface of the mirror. You can use a razor blade, needle nose pliers or just cut your fingernails to peel away this excess resin.

Step #5: Peel the stabilizer film away

You will notice that with some kits, it is difficult to stay within the crack. Don’t worry about this. There are 6-12 hours of exposure time for the epoxy resin after you apply it before it begins to fully harden. So once your mirror has set overnight, simply peel away all excess stabilizer film and clean up any rough patches on the surface of the mirror with sandpaper or a razor blade.

Step #6: Remove any excess epoxy resin

Use sandpaper to sand down rough surfaces so they are smooth again. Use more sandpaper if necessary until the surface is nice and even. You can also use gentle cleansers like Windex or alcohol wipes to clean the glass once more if desired.

Use a lubricant to wipe away any excess resin from the sides of the mirror. Make sure the mirror is clean and dry before doing so.

Step #7: Clean the mirror again

After you have removed all excess epoxy, use water (such as tap water) with a few drops of dish soap mixed in to gently wash the surface of the mirror once more. This should remove any remaining oils or fingerprints on the glass. Finally, rinse the mirror under cold water for 20 minutes to make sure no soap remains; otherwise, it will fog up your mirror (this also applies if you used Windex). You can let your newly repaired mirror sit overnight or for several hours if desired.

How Much Does It Cost To Fix A Cracked Mirror?

The cost to repair a broken mirror will depend on multiple factors, including the size of your mirror and how difficult the process will be. It is important to remember that if you do not feel comfortable repairing a broken frameless bathroom mirror by yourself, it is best to hire a professional. These mirrors can cost anywhere from $75 – $200 per hour for someone who knows what they are doing (if not more). If you make an error and crack your antique mirror, expect the price to go up exponentially because these types of mirrors require special care and unique skillsets in order to repair them properly.

Can You Use A Mirror Repair Kit For Large Mirrors?

Yes, mirror repair kits can be used for large frameless mirrors. If you would like to repair a larger mirror and it is too heavy to remove by yourself, we recommend hiring a professional mirror repairman (usually $75 – $200 per hour). However, if the job seems simple enough and you feel confident in repairing your own mirror, pick up some epoxy resin and follow our steps above.

Can You Repair Mirror Silvering?

Mirror silvering is a term used to describe a hazy or foggy reflection in a mirror, which can be caused by poor-quality glass or oxidation of the silvering layer. Mirror silvering occurs when there are impurities found in the glass surface and they scatter light as it reflects back from your face.

Fixing mirror silvering can be done fairly easily with some effort, patience, and epoxy resin. Sand down any rough patches on the surface of your mirror and clean it with water and dish soap (or Windex). Let the mirror dry for 20 minutes before doing anything else. Next, you will apply two layers of epoxy resin using our instructions above. The first layer is applied over your entire surface, and the second layer should be applied over any rough patches that you sanded down, as these are where silvering is most likely going to appear. Allow the first epoxy layer to dry for a few hours before applying a second coat.

Is A Broken Mirror Bad Luck?

There is no scientific evidence that breaking a mirror will lead you to seven years of bad luck. However, if the person who broke the mirror was unaware that it would cause them seven years of bad luck and did so on purpose, they would most likely experience negative effects in their life.

The most common interpretation behind this superstition is that whenever we see our reflection in a mirror, we are looking at what others see when they look at us. Therefore, if we break a mirror by accident or on purpose, it symbolizes that our image has been shattered and people will not be able to get a good read on who we truly are as an individual. This can then result in dishonesty, betrayal, or even miscalculations that lead to misfortunes.

Can You Throw Away A Broken Mirror?

If you break a mirror by accident, it is best to avoid throwing the broken pieces into the trash. Cover the pile of broken glass with a heavy towel and place it in a plastic bag. You will then want to tape this plastic bag shut and put it out for garbage collection (or drop it off at an appropriate recycling facility if your city offers one).

Do not attempt to throw away large mirrors on your own as they can be very dangerous if dropped or mishandled. We recommend hiring professional movers if necessary. Otherwise, ask friends or family members for help before attempting to move any broken mirror on your own – no matter how big or small.

What To Do With A Broken Mirror?

If the mirror was broken by accident, cover the pile of broken glass with a heavy towel and place it in a plastic bag. You will then want to tape this plastic bag shut and put it out for garbage collection (or drop it off at an appropriate recycling facility if your city offers one).

Epoxy and resin are two of the most popular adhesives for do-it-yourself projects. But they’re not interchangeable, so you need to know how to use them properly.

Many people think epoxy and resin are basically the same things, but that’s definitely not true. They have different properties and work differently in certain situations.

This post will explain how each adhesive works so you can choose the right one for your project needs.

Epoxy Coating Resin vs Casting Resin

Most people use epoxy or resin interchangeably, but they’re really two different types of adhesive with their own unique properties.

For the most part, you’ll be using epoxy coating resins when you want to fill in cracks and gaps in your project before coating it with something else.

Typically, these projects are not supposed to be clear so the color of the adhesive won’t matter too much when choosing epoxy or resin. That’s why many people prefer to use white glue instead – because it is cheap and easy to find.

However, if you’re looking for something that will bond well while remaining very clear after curing, then you should opt for a higher-quality acrylic epoxy resin like this one here.

Epoxy coating resins can be used for many different things such as:

- Filling in cracks and gaps that need to be filled

- Priming surfaces before painting or coating with something else

- Adding a decorative touch to furniture by filling in the wood grain first then adding another coat on top. As long as you choose epoxy resin that’s clear, it will remain stained glass-like after curing.

Casting resins, also called mold-making materials, are specifically designed for casting objects like molds and figurines. For the best possible results, you should be using a casting resin that cures completely clear.

A lot of people use these types of resins for making unique custom molds to cast concrete countertops.

You can also use this type of resin to make decorative objects like knickknacks or figurines.

Casting resins are much thinner than epoxy coating resins so they are easy to pour into small spaces without making a mess. But on the other hand, some people think they do not bond as well as epoxy coating resins.

This is mostly because curing time is much faster – sometimes just 5 minutes is all it takes. And since most projects require more than one, it is important to apply the resin in a way that will not trap bubbles underneath.

Casting resins are great for making molds but they do have limitations, so epoxy coating resins are usually better for most DIY projects.

Is Epoxy Resin Stronger Than Casting Resin?

Epoxy and casting resins both bond well to a variety of surfaces but neither one is stronger than the other. That’s because their overall strength depends on how you use them and what surface you’re bonding together.

Casting resins generally bond faster when compared to epoxy coating resin due to it being thinner, but epoxy coatings tend to bond pretty well too when used correctly.

Working with any type of adhesive requires patience and practice since there is a learning curve for every product. However, you should always make sure to test the adhesives first before using it on your final project (unless you want to fail).

Some people like to stick with epoxy coating resins because they believe that they are stronger, but this isn’t necessarily true. It just comes down to what type of situation you’re trying to fix or bond together.

Viscosity (Thickness Of The Material)

An epoxy coating is usually more viscous (thicker) than a casting resin due to its higher viscosity. After all, you want an epoxy or resin that can be used for filling in cracks and gaps without running everywhere.

Conversely, the viscosity of a casting resin will depend on its curing time. The longer it takes to cure, the less viscous it becomes.

When choosing between an epoxy coating or casting resin, consider how thick you need it to be before using it so you don’t waste your money on something with low viscosity.

You can always use both products interchangeably but just know that they work differently even though they’re both adhesives.

Cure Times

Another reason why some people prefer epoxy coating resin is that it has a longer cure time. But this isn’t always a good thing because that means you will have to stick around until the material dries completely.

In most cases, you should be applying your adhesive in multiple stages anyway, especially when working on large surfaces. In fact, adhesives with a long curing time may be susceptible to damage as they dry.

Casting resins only take 5 minutes or less to cure so this is probably one of their biggest benefits since you can work faster and get more done. However, there are some types of epoxy coatings that also have a fast drying time too if you don’t want to wait.

A suggestion for those of you who are just getting started with DIY projects is to get both types of resin so you can compare them for yourself.

Be sure to buy each material in small quantities since they’re only good for one project. After all, epoxy coating resins and casting resins usually come in very different size containers.

Working Time

The working time of epoxy coatings is usually longer than that of casting resins. This means you can simply pour it into its designated container, wait for it to thicken up, and then apply it.

Conversely, with a casting resin, you will have to work quickly before it cures. That’s why these types of resin are always sold in small containers – because they don’t last very long.

A general rule of thumb is that epoxy coating resin has the upper edge when working on large surface areas since it takes more time to cure. But if you need something fast with quick drying times, then go for a casting resin instead.

Maximum Pour Depth

The maximum pour depth for casting resins is usually much higher than that of epoxy coating resin. So if you want to make a deeper container, then you should use an epoxy coating instead (unless the container will be used for decorative purposes).

Also note that some epoxies can’t be poured over because it will ruin the surface. But there are other types of epoxy coatings that can withstand any material without problems.

When filling in cracks and gaps, most people prefer a casting resin since it’s more viscous so they won’t have to worry about getting adhesive everywhere or it dripping.

On the other hand, a good way to cover large gaps would be with epoxy coating resin which has a longer working time. Just make sure you place a barrier or something underneath it since this stuff can get messy.

Working Temperature Range

Epoxy coating resins have a wider working temperature range than most casting resins. So if you live in an environment with high heat or low temperatures, then go for epoxy instead.

However, there are some types of resins that can withstand extreme weather conditions so don’t worry too much about the working temperature when choosing between these two adhesives.

That’s because resin is more responsive to hot and cold environments than epoxy. That’s why resin is especially popular in industrial settings where the temperature changes frequently throughout the day.

Casting resin has another benefit when it comes to extreme climates – they’re easier to clean up. That’s because epoxy coatings will harden when exposed to water or other solvents so you’ll have a tough time removing it from your hands if it gets on there.

Stain Resistance

Since casting resins are often used in kitchens, bathrooms, and outdoors, these products have excellent resistance against stains.

That means they won’t yellow or deteriorate when exposed to sunlight – but you should still keep them away from moisture since that’s the only way resin can be damaged.

Even though epoxy coating resins don’t have a problem with UV rays, these adhesives may become degraded over time due to weather changes. So again, always make sure your epoxy coating is protected from the elements.

Environmental Impact

Both resin and epoxy work about the same in this area, but you should know that some resins may release a foul smell when mixed. So if you’re sensitive to these types of irritants then go for an epoxy coating instead.

However, there are many types of casting resins that don’t cause any bad odors so keep your options open. You can always try a few different materials to decide which one works best for you.

Hardness

When cured, epoxy coating resin has a higher hardness than casting resin. That’s why many people use it to cover surfaces that require maximum durability like garage floors.

On the other hand, there are some types of resins that may be more durable than others so you should always look at product labels before using any material.

This especially matters when choosing between different casting resins since they can all have vastly different levels of strength.

Also, keep in mind that epoxy coatings will usually be tougher than glue, but it still depends on the type of adhesive so don’t rule out castings just yet.

The only types of adhesives that can surpass both epoxies and resin in terms of unyieldingness are plastics and rubbers.

Speed of Application

If you need something in a hurry, then resin is definitely the way to go since it will dry in about 10 minutes while an epoxy coating will take an hour or two.

That’s why resin is great for small projects that need to be done quickly like masking the legs of a table.

Epoxy coating and casting resins can both be used multiple times (it just depends on what you’re trying to construct) so you don’t have to worry about wasting your material when building with either adhesive.

No matter which one you choose between epoxy coatings and castings, always wear protection. In addition to gloves, I would recommend safety glasses since resin may cause irritation in some people.

All in all, both materials have their pros and cons but it’s up to you to decide which product is best for your needs. Experiment with a few options until you find the right material, and remember that this type of project will require a lot of patience.

UV Resistance

Resin doesn’t have a problem with UV rays, but epoxy coatings may become degraded over time due to weather changes. So again, always make sure your epoxy coating is protected from the elements.

Susceptibility To Bubbles

When it comes to bubbles, resin is actually more susceptible since epoxy coatings are thicker. But don’t worry. There are simple techniques you can use to make sure the adhesive will be bubble-free.

You should first apply a proper primer to your surface before adding an epoxy coating or resin adhesives. This helps the material stick better and also provides protection against various external elements like water.

Don’t worry about spending too much energy on priming either since this step usually only takes 5 minutes – especially if you’re using a product that’s specially made for priming.

Next, always stir your product very well until all of the solids are incorporated into the liquid base. Resin may have some tiny particles floating around, but these won’t cause any problems as long as you’re diligent about stirring. For best results use an electric mixing tool like a power drill to mix your epoxy coating thoroughly.

Once your adhesive is mixed properly, apply it slowly in a thin layer and let it dry for the designated amount of time. You’ll notice that bubbles usually start forming when the coating is still wet so do everything you can to avoid applying too much product at once.

You should be able to cover about 15 square feet with one quart of resin or epoxy so don’t try to use too much. Wasting this type of material is a bad idea since it’s not exactly cheap, so always read product labels before you begin working on a surface.

When using epoxy coatings, keep in mind that they might take even longer to dry than resin adhesives. This is because epoxies do not form a skin as quickly as resins do so it’s much harder to see when the adhesive has cured.

This means that you may need to leave your surface-exposed overnight or until you notice a slight change in color. If there are any small cracks or crevices on the material you’re working on, then expect these areas to be especially vulnerable to moisture. That’s why epoxy coatings should always be applied over a primer – this will protect the adhesive from water damage and make sure it lasts for years.

All in all epoxy adhesives actually work very well when applied correctly, and they offer a more durable long-term solution than resin.

But if you need to make your surface faster, then resin is the best option for you… And if epoxy is still what you’re looking for, then make sure you use a primer before applying the adhesive since this will prevent water damage. You should also apply epoxy coatings in several thin layers instead of one thick one – otherwise, bubbles might be more likely to form during the drying process.

Heat Tolerance/Resistance

Heat is actually not that much of a problem when it comes to resin, but epoxy coatings may start to deteriorate when exposed to extreme temperature fluctuations.

But once again, keep in mind that the resin you’re working with should be mixed very well before applying. If there are any tiny particles floating around or if your adhesive is too thick, then these may cause bubbles and other problems later on. So always make sure you mix thoroughly and apply the product in thin layers until you get the desired results.

Last but not least, never ever pour leftover resin (or epoxy) down the drain. This will result in clogs and can even damage your septic tank so just let this stuff dry out and throw it away afterward.

Price Comparison Between Epoxy And Resin Adhesives

This is where it gets tricky since prices vary from product to product – even within the same category. But overall, I’d say that epoxy coatings have a slight edge on most resin adhesives.

But of course, there are always exceptions to the rule so don’t be afraid to get a little creative with your choices. Just make sure you get something good since it will depend on how everything comes out in the end.

That’s because resin is more responsive to hot and cold environments than epoxy. That’s why resin is especially popular in industrial settings where the temperature changes frequently throughout the day.

Even though epoxy coating resins don’t have a problem with UV rays, these adhesives may become degraded over time due to weather changes. So again, always make sure your epoxy coating is protected from the elements.

Epoxy vs Resin: Which One Is Best For Me?

If you’re working on a project where appearance isn’t too important then white glue is probably fine since it’s cheaper and easier to find at most hardware stores. Unfortunately, there are times when both epoxy coatings and casting resins do not work well… especially if the adhesive needs to be useful in underwater applications.

If that’s the case, then you’ll need to find out which type of adhesive is best suited for your specific project before buying anything. For example, waterproof epoxy resin can repair cracks in fiberglass boats while marine-grade epoxy adhesive can bond wood together underwater.

Once you’ve made up your mind on what type of adhesive or resin you need, it will be much easier to choose between an epoxy coating and casting resin because they both serve very different purposes. Epoxy coatings are thicker but thinner coatings may work better when trying to fill small gaps since they generally take less time to dry compared to other adhesives. On the other hand, casting resins are much thinner but they’re also a lot more likely to trap bubbles if you don’t pour it the right way.

The only way to find out which works best for your specific needs is to test each one first, so always make sure that you do your research before shopping around.

If you’re a DIY’er, then chances are that at some point you’ve considered using epoxy resin to fix something.

Epoxy resin is a great way to fix things around your house, but it can be hard to figure out how much of the stuff you need and how best to use it.

In this blog post, we’ll tell you everything there is about epoxy resin so that next time something breaks in your home or office, you’ll have all the information necessary to fix it with ease.

What is Resin?

Epoxy resin is a material that’s created by mixing two components together. This creates a chemical reaction that causes the epoxy to harden and become solid, which can be used as the glue or as a coating for other materials such as wood

The components of the epoxy are mixed in a 1:1 ratio, which means they’re combined in equal amounts. Different types of resin have different pot lives – how long it takes before the chemical process produces any noticeable changes – and demold times – how long it takes before the hardened resin can be removed from whatever it was used on.

Types of Epoxy Resin

There are many different kinds of epoxies available around the world, with each country having its own variations based on what they’re typically used for and how long they take to set.

Regardless of their country of origin, the most popular types of epoxy resin include:

Classic – this is a two-part epoxy with a fast pot life and demold time. An example of classic epoxy resin is J-B Weld, which has been around for decades and can be found at virtually any hardware store.

Rapid – these are one-part epoxies that set extremely quickly and have short demold times. They’re best used in applications where you need your final product to be finished as soon as possible.

Epoxy putty – these come as bars or liquids and dry into firm solids that can be sanded or drilled like wood. A popular type of epoxy putty is J-B Weld KwikWood, which hardens just like real wood.

Epoxy Adhesives – these are one-part adhesives used to bond two materials together. An example of an epoxy adhesive is Araldite, which can be used for crafting and repairing items such as jewelry or model cars.

Grout – these come in a variety of different forms and colors and dry into smooth finishes that don’t require any sanding. They’re most commonly used around the home to fill gaps on walls or between tiles.

Casting resin – these resins create firm yet flexible products that last over extended periods of time without losing their shape or texture. Casting resins ensure your final product won’t break over time.

What is Epoxy Resin Used for?

There are a lot of different uses for epoxies around the house, but they can be particularly useful in the following applications:

Fixing Things Around Your House – whether it’s fixing a chair or repairing a crack in your windshield, epoxy resin is one of the best ways to fix things around your home. Simply apply some resin and let it dry until you have a smooth finish that lasts.

Laminating Paper or Other Thin Materials – many people use epoxy resin as glue. It doesn’t dry transparent like most glues, which means it stands out on whatever material you’re laminating together. A popular example of this is when people laminate their business cards to give them a more professional finish.

Making Art Projects – epoxy resin is popular with hobbyists and professionals alike. It can be used to create sculptures and other types of art that would normally require expensive materials like silver, gold, or marble.

Filling Gaps – epoxies are extremely versatile. They can be used to fill gaps around the home, which might otherwise need an entire tube of caulk or a lot of time with sandpaper.

Curing Natural Materials – many natural materials have pores that trap air and prevent them from properly hardening. Epoxy resin can fill these pores so your final product won’t crack as easily over time.

How is Epoxy Resin Applied?

Epoxy resin comes in many different forms, but one way or another it’s going to have to be applied somehow. The basic steps you should follow when applying epoxy include:

Clean Up Surfaces – first, clean up any surfaces that you’re planning on working with. If necessary, clean them with alcohol or acetone to remove all remnants of dirt, dust, oil or grease.