It’s easy to become confused and overwhelmed when trying to figure out the right materials to use, such as screws and nuts.

We’ve found thirty-six types of screws commonly used and compiled them into this resourceful ultimate guide. We will talk about each of these screws, their features, and typical uses.

By the time you finish this article, we expect you to be a screw master! Here we go.

The 36 Types of Screws

You may be surprised to see how many different screws are available. Here’s our custom graphic, a brief description of the 36 screws that are most common.

#1. Decking screws

Deck screws are a must-have if you’re putting together a deck, patio, or other heavy load-bearing structures.

If you’re unfamiliar with the many various types of screws, you may unintentionally confuse decking screws with wood screws due to their similarities.

However, deck screws are copper or coated steel material, making them strong and resistant to corrosion – a must for screws used outdoors.

Deck screws have a flat head, similar to wood screws, but the head is larger, so it can support more weight. Another notable difference is that the head will have a slight flare or bugle shape that keeps the screw from sinking into the wood, causing cracks or splits.

Another trademark of deck screws is sharp, deep tapered threading along the skank with an aggressive tip.

#2. Pan-head screws

Pan-head screws are a great solution when you need a decorative look, or there’s potential to run into the head. Machine screws like these require a pre-drilled and threaded hole due to the flat tip.

These screws have a broad head that’s flat or slightly domed with high, chamfered, or curved edges that create a deep socket. The bottom is flat, which provides a firm hold and reduced crushing. These screws are ideal for enlarged holes.

Pan-heads can be compatible with multiple socket types: slotted, hexagon, Phillips, square, Torx, or Pozidriv. And there are numerous coating options: stainless steel (white, black, or non-coated) or zinc-plated.

#3. Hex cap screws

Hex cap screws are a type of fastener that’s commonly confused with hex bolts. These screws have a hexagonal head (six sides), a washer face that lays flush with the bottom of the screw, and a chamfered point.

This type of screw is common in construction and the assembly of machines due to their ability to secure a tight fit. To install a hex cap screw, you turn the head to feed the threads into the tapped hole.

There are multiple grades of hex cap screws. Grade 2 screws are low carbon steel and useful for securing wood or light hardware that doesn’t require a lot of strength. You do need to use nuts and washers with hex cap screws.

Grade 5 fasteners are medium carbon steel that goes through quenching and tempering to add extra strength. These screws are often used in the automotive industry.

Grade 8 hex cap screws are medium carbon alloy steel that has been quenched and tempered to the hardest strength possible.

And the most common type of hex cap screw is 18-8 stainless steel, a composite made of 18% chromium and 8% nickel. These screws resist corrosion and have high strength. This category consists of multiple grades of stainless metal (302, 303, 304, 305).

#4. Carriage bolts

Carriage bolts are fasteners made of stainless or galvanized steel to secure wood and metal materials. Both materials mean that these screws are corrosion and scratch-resistant. Other common names are a coach or plow bolts.

These screws have a round head, with a straight threaded shank (the bottom half is threaded, the top half is smooth metal) and a flat bottom.

You will need to predrill holes before placing carriage bolts and tapping them into place with a hammer. Secure your bolt with a nut and bolt.

Carriage bolts are versatile enough to use in multiple ways, including farming, railroad, and mining industries.

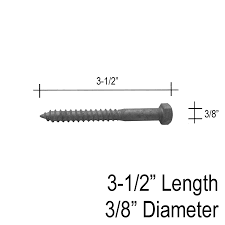

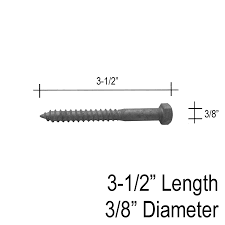

#5. Lag bolts

Lag bolts are a thread-forming wood screw with a gimlet point (threaded cone tip) with a 45 to 50 angle. These screws are ideal for securing wood to wood or metal and for mounting to masonry or concrete.

The coarse, wide threads and the pointed tip means that you can use these screws to create your hole – no pre-drilling required. And because the threads mate with the material, you don’t need a nut to keep it secure.

The lag bolt size can range from ¼” to ¾” diameter and 1″ to 16″ in length. The head is typically hex-shaped, and the size varies. You need to ensure enough room around the head to fit a wrench to secure the bolt fully.

These bolts are usually steel or stainless steel construction. You can get these with hot-dip galvanized or zinc plated finishes making these screws non-corrosive. When using pressure preservative-treated wood, it’s best to use galvanized or stainless steel.

#6. Hammer drive screws

Hammer drive screws are self-tapping permanent fixing for heavy-duty use. These screws are also known as U-drive, drive, or unslotted round head.

U-drive screws have unslotted, round heads that require a hammer to secure them in place. Although these screws can mate with a surface once pushed through, you need to drill a small starter hole before inserting your screw. And your screw must be harder than what you are mating.

Hammer drive screws are 316 or 18-8 steel and can have zinc or black oxide finishes. These have a non-threaded pilot point tip and large helical angled start threads.

#7. Square Head bolts

Squarehead bolts have a broad square head with plenty of room for a wrench, which is needed to mate these bolts to their surface.

This type of bolt is preferable when you want a rustic theme or match older bolts in a building restored. These bolts are also used in the railroad industry.

Squarehead bolts can have a full thread or partial thread, ranging in size from diameters of ½” to 1 ½” and lengths of 1″ to 17-inches.

Materials used for square head bolts include plain steel or steel with zinc or hot-dipped galvanized finishes.

#8. Socket-head cap screws

Socket-head cap screws are known by many names, including socket cap screws, Allen socket bolts, or socket screws. Socket screws are an everyday use in machinery.

These screws have a cylindrical button head cap screw with a hexagonal hole. You can get a socket head screw with a button, cap, flat, or flange head. To drive a socket-head, you will need a hex Allen key or an appropriately sized socket wrench.

You can find these screws with a full or partial external thread. There are metric or inch sizes, with various lengths and diameters made of stainless steel, silicon bronze, or Ni-Cu Alloy Steel.

#9. Oval head screws

Oval head screws are countersunk screws with an oval head and a decorative finish. These screws are often used for mounting switch covers and lay flush against the surface.

However, the head’s roundness does mean the screw will still stick out of the plate slightly. Oval head screws have a cone-shaped underhead with a tapered shank.

You can also get an undercut oval head screw, which differs from a regular oval head by the head underside’s flat bottom. This design provides an entirely flush look.

#10. Wood screws

Wood screws are a common sight in garages and workshops. If you’re making furniture, cabinets, or mounting something to your wall, you’ll need this type of screw. It’s a versatile tool that you’ll use on many projects.

You can get wood screws with pan, oval, or flat heads that lay flush into the wood. With some projects, this deep-set can cause the wood to damage.

Wood screws have a straight shank with medium threading and a sharp tip. However, the top part of the shank is smooth instead of threaded, up to the head. Wood screws share a similar thread look to deck screws.

Because wood screws are steel, they cannot stand up well to wet conditions. Steel will start to rust and corrode with frequent exposure to water.

#11. Sheet metal screws

Sheet metal screws are a versatile fastener you can use to secure plastic, wood, and metal. This type of screw has a fully threaded shank with sharp grooves that mate with the material for a secure hold.

Self-drilling screws have a sharp conical tip that allows you to start the hole using your screw, while self-tapping screws require you to predrill a starter hole before inserting your screw.

The size of sheet metal screws is displayed as three numbers. The first is diameter, then thread count, and the final number is the length.

Sheet metal screws come in multiple head types – Pan or round heads stick out from the surface, while flat or oval countersunk heads will flush. They may be flat, Phillips, or combo drive.

The most economical sheet metal screws are of carbon steel, which is not weather-resistant. For a higher price, you can get galvanized stainless steel, which is better for outdoor use. Zinc or nickel-plated screws are also available.

#12. Thread-rolling screws

Thread rolling screws are an excellent option for drilling into materials like plastic or sheet metal. You need a predrilled hole for thread-rolling screws to work.

These screws have a trilobular lobed cross-section that pushes material from the hole while drilling through the surface. If you want to reduce loose chips, you should use thread-rolling screws.

Thread-rolling screws are steel or 18-8 or 410 stainless steel that has been quenched and tempered for extra strength. You can get these screws in a range of diameters and lengths.

#13. Socket-head screws

Socket-heads are a type of machine screw that has a cylindrical barrel head with a hexagonal socket. Other names for socket-head screws are socket head cap screw, hex socket head screw, or cap head socket screw.

The most significant difference between a socket head screw and other types is the smaller size head, which is 1.5 times bigger than the thread’s nominal diameter. This feature makes these screws perfect for tight spaces.

Typical uses of a socket head cap screw are in sporting gear, like bikes, where there’s a need for a flush setting, so there’s no potential for catching on exposed screws. This screw type creates a recessed set where the cap head sits flat inside a counterbored hole.

When purchasing these screws, remember that the described length includes the shaft and head. The measurements of this screw type use two numbers with a point in the middle.

This dot is not a decimal but a separator between the first number – ultimate tensile strength (UTS) in MPa then divided by 100; and the second number – the yield strength to UTS ratio.

The head of a socket cap screw can be a flange button, button head, flat head, metric, or socket, made of 304, 18-8, or 316 stainless steel. Chrome-plated steel is also available.

#14. Set screws

Set screws are a type that applies pressure at the tip to secure objects, rather than using the threads. This design does not contain a head and needs a tapped hole before installation. You also will need a hex socket or key.

There are different point types for set screws. A cup tip contains a thin edge that bites into the surface for a firm hold on hard or soft surfaces. Knurl-grip cup tip has serrations around the edge of the cup. The end of a flat set screw is flat, ideal for securing to a flat surface.

Oval tips are useful for U or V-shaped or angled surfaces. Cone set screws have a sharp point for securing soft materials. And the extended, or dog-point, set screw has an extended tip that mates with a slot or hole.

Set screws come in multiple materials, including 18-8 or 316 stainless steel, nickel alloy, brass, or plastic. You can also get them with black oxide finishes.

Set screws come in multiple diameters and lengths, and both metric or inch hex sizes.

The screw size is listed as the thread diameter (inches or metric) and threads per inch. The second number will be the thread distance in metric sizes, measured in mm.

#15. Weld screws

You can use weld screws to produce a protruding shaft. You have to weld these screws to a metal surface and secure your items using a washer and nut.

There are three weld screw designs. These are bottom projection spade projection or top projection screws.

Weld screws come in various lengths, diameters, and thread counts. Once welded, these screws become permanently attached to the mount.

#16. Raised or slotted cheese screws

Cheese head screws have a round head that resembles a wheel of cheese, hence the name. This screw will have a flat disc top head that’s round on all sides with a flat bearing surface. The height of the head is half the diameter.

Cheese screws are a type of cap screw used in automotive, bicycles, electrical, and appliances. Pan head screws have primarily replaced slotted cheese screws, but these are still preferred when there’s a need for a deeper socket and strong head strength.

There are multiple drive types, including slotted – the most common – and crosshead, Allen, spine, hexalobular, and Pozidriv.

Raised cheese head screws are called fillister screws. It has the same cylindrical sides and a flat mating surface, but the head is domed and deeper.

#17. Fillister head screws

Fillister head screws are often referred to as cheese head screws due to the cylindrical head shape. This screw has similarities to pan head screws. However, they have higher sides.

The head of a Fillister screw is oversized with a slight convex. These screws are great for connecting metal to metal or wood to wood. However, they are rarely used in new production, so you’ll likely need these as replacement screws for older material.

Materials of a Fillister screw are typically A386, 18-8, or 316 stainless steel. Grade 5 titanium, brass, plastic, or alloy steel. Zinc or black oxide finishes are also available.

#18. Drywall screws

Drywall screws hold drywall into place without damaging your surface. However, these screws are not for building.

When picking your screws, you’ll want to base the length on the size of your drywall.

- ¼” drywall – 1″ to 1 ¼” screws

- ½” drywall – 1 ¼” to 1 ⅝” screws

- ⅝” drywall – 1 ⅝” to 2″ screws

You’ll also need to consider the threading on the screw. Fine-threaded screws self thread and are great for metal studs but not wood. For wood studs, you’d want to use a coarse thread.

The gauge, or diameter of the screw, is also important to consider. To hang drywall, the best screw gauge is #6 or #8. The larger the gauge, the thicker the diameter. A #6 screw is 0.1380” and a #8 is 0.1640.”

#19. Concrete or masonry screws

Concrete and other masonry are hard surfaces that need concrete screws. The best concrete screws to use are self-tapping.

You do need to predrill a hole before inserting a screw into the concrete. It should be slightly deeper than the width of the screw. After removing the dust from the hole, insert your screw and thread it into position.

The dimensions are two numbers. The first is the diameter – either 3/16″ or ¼,” and the second number represents the length – 1 ¼” to 6.”

Concrete screws can have a Phillips head, which allows for a countersunk fit, or a hex head that creates a raised fit over the surface.

These screws can be carbon steel or 410 stainless steel, which is better for outdoor use or areas where there’s high moisture.

#20. Machine screws

Machine screws have a uniform shaft with evenly spaced threads of ¼” or less diameter. Threading can be coarse – 24 threads each inch or fine – 32 threads per inch. These screws are used in appliances, automotive, electronics, tools, and machines.

Machine screws have various heads, such as standard slotted, Allen hex sockets, square-drive, security, Torx six-pointed star, and Phillips heads.

The best thing about machine screws is they can fasten multiple types and amounts of joints. You can secure machine screws with nuts, threaded into a surface, or with threaded couplings. These screws are quite versatile.

#21. Modified truss screws

Modified truss screws, also called self-piercing screws, have a sharp piercing tip that can start and make holes without predrilling.

The head is more extensive, so there’s more material to cover the surface for a tighter fit. A Phillips drive slot sits higher above the flat rim.

This type of screw is used for securing lath (thin pieces of wood) or corrugated siding to steel or wood bases. They’re also frequently used in HVAC.

Modified truss screws are stainless steel and can be painted or zinc coated. These come in multiple lengths in a #8 gauge.

#22. Washer-faced screws

Washer face thumb screws are a solid piece screw with a full unified thread along the shank and a flat, smooth cylindrical head.

These screws have knurled sides and a two-piece shoulder that separates the head from the shank. The broader part of the shoulder holds the washer face.

Washer-face thumb screws are stainless steel or aluminum and come in various lengths and thread counts. You need to predrill a hole before inserting these screws into the surface.

#23. Thread-cutting machine screws

Thread-cutting screws are self-tapping, which means they cut new threads through metal when put into an existing hole. These screws are commonly used in places where there’s the need to remove them frequently.

This type of screw has a flat head with a conical neck and a uniform thread along the shank. The tip is flat, so it can’t pierce to start a new hole. But unique grooves cut into the threads allow these screws to rethread an existing hole.

There are five types of thread cutting machine screws for metal, plastic, or wood: Type 1, Type 17, Type 23, Type 25, and Type F.

Type 1 screws have a single flute that creates a fine standard thread. Type 17 is better for wood and has a coarse thread and a long fluted sharp point on the tip that catches chips.

Type 23 screws cut fine wide threads and remove a large portion of chips. A similar design is the Type 25, which has a coarse thread with a large cutting edge great for plastic and soft materials.

F screws have a blunt, tapered tip with multi-cutting edges and chip removal. These are ideal for heavy gauge metal, zinc, aluminum, cast iron, brass, and plastic.

#24. Self-drilling SMS

Self-drilling sheet metal screws (SMS) is the most common fastener used in industrial settings. These come in a variety of lengths, diameters, and drive types.

These screws have a sharp drill point on the tip that allows you to use these screws to start your hole and drill through the material without predrilling a spot.

Sheet metal screws are often confused with self-tapping screws, which have mating threads that hold in a pre-piloted hole.

But it’s important to remember that there is a difference between self-tapping and self-drilling. Both are for sheet metal. All self-drilling screws are self-tapping. However, not all self-tapping screws are self-drilling.

#25. Self-tapping screws

Self-tapping screws can work on a variety of materials, including sheet metal, plastic, or wood. These are often called sheet metal screws because they are widely used in industrial settings.

These screws have a sharp, pointed tip with a tapered threaded shank. They come in different head shapes, drives, diameters, and lengths.

Self-tapping screws can create new threads, but they require you to create a pilot hole first, using a drill bit slightly smaller than the screw’s diameter. Once the initial hole is made, you can use the self-tapping screw to create the hole.

#26. Framing screws

Framing screws, sometimes called bugle heads, are used in construction when framing a building. Some types of framing screws are for installing drywall or gypsum board.

The most common type for connecting two by fours is a 2 ½” #9 or #10 hardened steel screw. You can get these with hot-dipped galvanized coating for better corrosion resistance.

These screws typically need to be long enough to go through a 2×4, which is 1 ½” thick, so a minimum of ½ is necessary. However, using a screw that’s too long can waste time and damage the wood.

This type of screw has a flat or concave head with a thin rim and a diameter between ¼” and 5/16″ with various drive types – square, Torx, Phillips, hex-head, and T-star.

#27. Tamper-resistant screws

Tamper-resistant screws are ideal in places where you’re trying to prevent unauthorized entry, such as on electrical or HVAC panels.

These screws require a specific tool to fasten or remove. You cannot use a standard wrench or screwdriver, making them less likely to be accessed without the proper tools.

There are various types of tamper-resistant screws, including full, half, or partial thread shanks. You can also find different head types, including:

- Flat bolts (non-countersinking)

- Button head

- One side pan head

- Triangular socket button head

- Triwing flat head

- Flathead bolts

There are even ones you can use with washers and nuts to create a secure, tamper-resistant hold for your secured items, such as cameras or interlocking devices.

#28. Mating screws

Mating screws are one half of a set and require a sex screw to be complete. Mating screws have an unthreaded shoulder and a threaded shank.

When you attach the sex screw, it fits over the mating screw, and the threads mate together to form a hold.

Mating screws come in metric and imperial sizes with various thread options, including ACME, ISO, BSW, UNC, and UNF.

You can choose from a full or partial threaded mating screw. Be sure the sex screw is the appropriate match for the selection you make for your mating screw. The diameter of the unthreaded shoulder should be the same as the outside of the sex bolt.

#29. Sex bolts

Sex bolts, also called Chicago bolts or barrel nuts, look similar to machine screws with a smooth, unthreaded shank. The inside of a sex bolt has threads that screw over the top of the mating screw.

These screws can have multiple drive types, including hex socket, flat head, button head, truss head, Phillips, slotted, or 6-lobe Truss heads.

Sex bolts and mating screws can be used in many assembly applications and require a predrilled hole.

Length, diameter, and threading vary, so you’re sure to find a set that fits your required parameters.

#30. Eyebolts

Eyebolts have a unique look that makes them easily identifiable among other screws. These screws have a threaded shaft with a ringed head that can be enclosed or open.

This eye is open, so you can thread through a rope, cable, or hook. Eyebolts are commonly seen on machinery like cranes or as a design feature to secure items that can’t be screwed or nailed.

Eyebolts that do not form an enclosed circle cannot sustain off-axis loads, while closed rings have a closed weld, so they have more strength.

The different eye bolts are anchor eye bolts, screw eyes (also called eye screws), ring bolts, eye nut, pigtail eye bolts, or roller eye bolts.

#31. Eye lags

Eye lags are a type of eye bolt used for wood. These screws are also called turned/bent eye lags, screw thread eye bolts, or eye screws.

These screws work as an anchor but are not intended for heavy loads. They have a threaded shank with a sharp-pointed tip that helps the screw stay secured in the material.

The top of these screws has the expected eye, made from bending the unthreaded metal into a loop. Like eyebolts, eye lags can have an enclosed or open ring.

#32. J-bolts

J-bolts are a common type of fastener used in concrete formation and construction. These may be used for building new foundations, a garage, or attaching a new wall to concrete around the house.

These bolts get their name due to the signature “J” shape. They have a long threaded shank that ends in an unthreaded hook on the bottom.

You install these hooks onto rebar after the cement has been poured and smoothed, but before it dries. Once the concrete cures around the bolt, it becomes an anchor.

You can get J bolts in multiple lengths and diameters. Bolts with ½” diameter are the most common for residential construction.

#33. U-bolts

U-bolts are a piece of steel formed into a “U” with threading on each end. These bolts are ideal for fitting around tubing or pipes.

You can find U-bolts in carbon steel, 304 or 316 stainless steel, and coated with zinc, fluoropolymer (PTFE, Teflon, or Xylan), thermoplastic or hot-dipped galvanized.

Sizing varies for U-bolts, from as small as a ¼” diameter up to an inch and various lengths and widths.

U-bolts require nuts to secure them into place, which usually comes with the part. Once you get your bolt where you want it, put a bolt on each threaded end and tighten it with a wrench or power tool.

#34. Shoulder bolts

Shoulder bolts, also called stripper bolts or shoulder screws, are a type of machine screw that has a shoulder between the thread and the head.

This type of screw is not often used in residential settings but is common in many consumer products.

There are three main parts of a shoulder bolt – thread, shoulder, and head. The thread should have a slightly smaller diameter than the shoulder, and the head should have the largest. The size is displayed by the diameter of the shoulder and then the length.

#35. Elevator bolts

Elevator bolts have a broad flat head with a standard square bolt head underneath, separated from the threads. This head rests countersunk so it can be tightened or loosened easily. The flathead part of the bolt rests flush against the surface for more weight resistance.

You can get elevator bolts in various lengths and dimensions, as well as drive type.

The most common uses for elevator bolts are on conveyor and lift machines, floors in automobiles, bucket lifts, and soft surfaces like wood.

#36. Hanger bolts

Hanger bolts have two separate ends – one pointy insert into the wood, and the other is flat and inserted into a threaded insert.

Hanger bolts are often used for installing legs onto furniture or working with crafts. Because both sides are threaded, you’ll have to predrill holes before inserting a hanger bolt into your material.

Use caution when installing these screws, so you insert the right side. The pointy tip should go into the wood while the smooth based side attaches to a plate.

Types and Shapes of Screwheads

Screws can have many different shapes of heads and require different tools to install. All screws will fall into countersunk or non-countersunk.

The difference between the two is non-countersunk heads are fully exposed or stick up from the surface. Countersunk heads lay flush against the surface.

Types of non-countersunk heads include a button, cheese, binding, fillister, round, flange, socket, low socket, hex, pan, square, or truss. Binding heads are also called binder heads.

Countersunk heads are flat, bugle, or oval-shaped. Some of these types can be covered by a beauty cap or a screw cover that disguises the screw’s presence.

In some cases, there is a combination of these, like slotted hex washers, round washer heads, slotted hex, or hex washers.

Drive Types

Drive recess is the notch in the top of your head that coincides with the type of tool you need to install or loosen the screw.

Phillips, slotted, hex, hex socket, combination (Phillips and slotted), Torx, spanner, or square are the most common drive types.

Slotted, combination, and one-way screws use a screwdriver. Phillips screwdrivers should be used for Phillips or combination screws. Hex sockets need a hex key. And Torx drivers are necessary for Torx screws.

Washer Types

Some types of screws will need washers or small round discs. There are three primary types, and which one you would need will depend on your needs and the screw you’re using.

Washers can be various materials, with the most common being stainless steel or galvanized carbon steel. There’s also iron, copper, brass, or zinc-coated washers.

The three types are lock, spring, and plain washers. All washers come in metric or imperial measurements.

Plain, or Type A, washers are a flat disc with a center hole that fits over a bolt’s shank. These can range in size and thickness. Other types of plain washers include fender, torque, finishing, or C-washer.

Spring washers have better resistance to vibrations, so they stay fastened and tight. These washers include Belleville (conical spring), crescent (curved spring), dome, finger, or wave springs.

Lock washers prevent fasteners that rotate. The different types are split lock (helical washers), external tooth lock, or internal tooth lock.

Nut Types

Nuts go on the end of some types of screws to provide a tight, secure hold. As with most hardware, there are many different types. Which one you use will depend on your screw type.

Common nut types are:

- hex nuts (have six sides and installed on hex bolts with a wrench),

- jam nuts (half the height of standard hex nuts),

- lock nuts (also called prevailing torque nuts),

- push nuts (requires a specialized nut driver and can be uncapped or capped),

- rod coupling nuts (extension nut that has a hollow threaded center),

- speed nuts (sheet metal nuts)

- Square nuts (a four-sided square with internal plating)

- Tee nuts (long threaded body with a flange on end)

- U-nuts

- Wingnuts

Conclusion

We hope we’ve helped shed light on the many different types of screws. We’ve listed the 36 most common screws you may encounter in residential, commercial, and industrial settings. We’ve also covered the different types of washers, nuts, and drive recesses.